CALORPLAST’s thermoplastic gas-liquid heat exchanger is an essential process device for heat transfer from a gaseous (vapor) medium to a liquid medium. Built from high-quality thermoplastic materials, this heat exchanger is ideal for heat recovery, as well as cooling and heating large gas flows.

Our heat exchanger finds its main applications in a variety of industries, including surface finishing, chemical processes, electronics, and more. It is perfect for energy recovery from corrosive exhaust air, cooling and heating aggressive exhaust gases, ventilation installations, and condensation of vapors in the chemical and pharmaceutical industries.

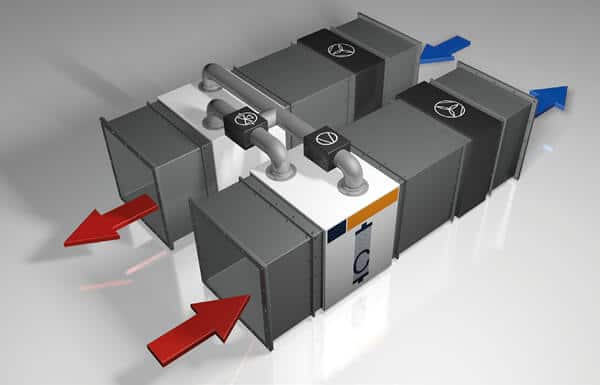

Our product range is modular in design, capable of handling gas volume flows up to 90,000 CFM. For gases containing entrained droplets or moisture, our heat exchanger can be fitted with a mist eliminator, along with an internal wash-down system for easy cleaning. The gas-tight casing is fabricated from heavy-walled thermoplastic sheets and contains a condensate collector, reinforcing ribs, and flanges. Trust CALORPLAST for your thermoplastic gas-liquid heat exchanger needs.