CALORPLAST’s all-plastic tube plate heat exchanger is a versatile external shell-and-tube type heat exchanger designed for efficient heat transfer between low-viscosity fluids. Suitable for clean or moderately polluted media, this heat exchanger can be used for heating, cooling, and condensing vapors.

Constructed with corrosion-resistant plastics on both sides, this thermoplastic tube plate heat exchanger finds its applications in various industries such as surface finishing, chemical processing, biogas generation, saltwater aquariums, semiconductor, and pharmaceuticals.

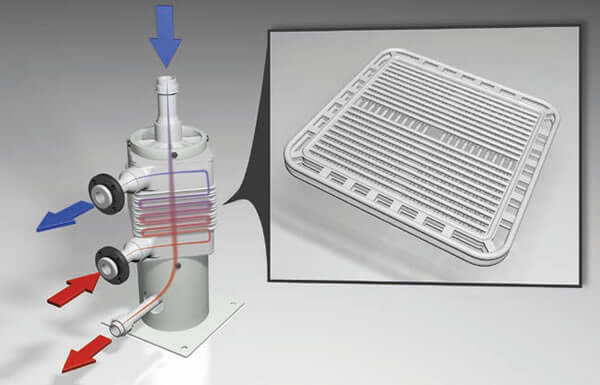

Featuring a unique modular design, individual “tube plates” are combined into a double-walled thermoplastic pressure container and welded without any additional materials. By arranging the tube plates in different alignments, the heat exchanger can handle various flows.

Every CALORPLAST heat exchanger is optimized through a computer-aided simulation for the best configuration to meet your specific requirements at a reasonable price.

Cleaning this heat exchanger is as easy as counter-flushing.