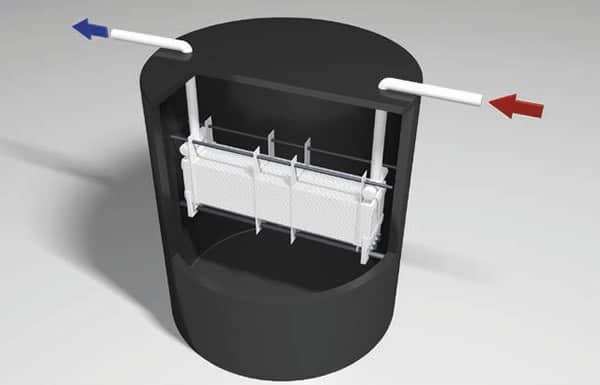

Introducing CALORPLAST’s all-plastic immersion-type grid coils – the perfect solution for a variety of heating and cooling applications. Our grid coils are specifically designed to handle concentrated inorganic acids, alkaline corrosive liquids, high-purity media, and even aggressive and scale depositing liquids in tanks and other process equipment. They are widely used in the surface finishing and chemical process industries.

Our PVDF grid coils are specially designed for steam heating of corrosive media such as inorganic acids used in the steel picking industry.

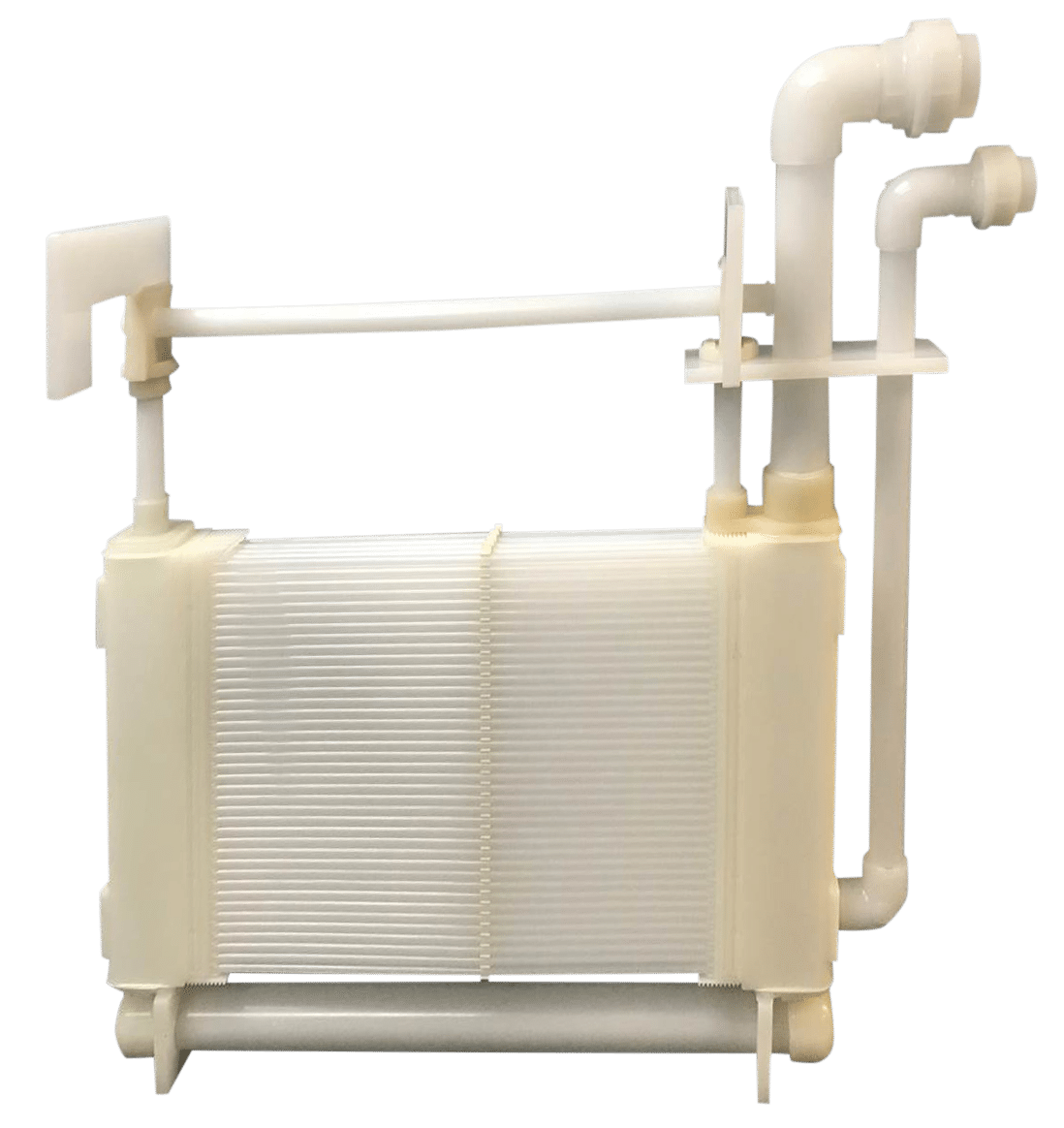

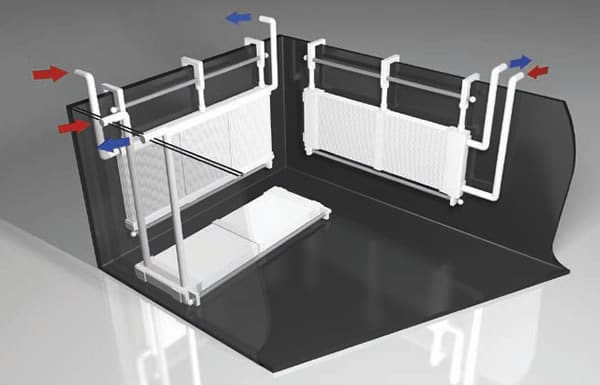

We pride ourselves on offering the most optimal design to meet our customers’ unique specifications. Our thermoplastic heating and cooling grid coils are fabricated from standardized tubular modules, with fittings and support elements designed according to each customer’s needs.

Our unique manufacturing process ensures minimal pressure loss while providing high heating/cooling performance. The modular design allows for customization of the heat exchanger fabrication to create the most efficient cooling or heating flow, using minimal space in the tank.

Our heat exchangers are calculated and optimized using computer-aided simulation, allowing us to create the most reliable configuration at a reasonable price. Plus, our heat exchangers are easily cleaned using pressurized water, steam, or chemicals, ensuring a long operating life.

Choose CALORPLAST for high-performance, efficient, and reliable all-plastic immersion-type grid coils.