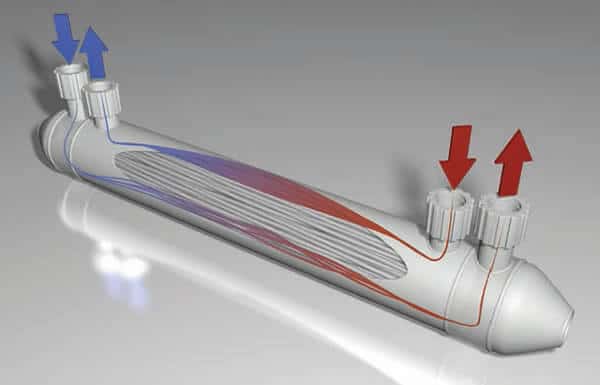

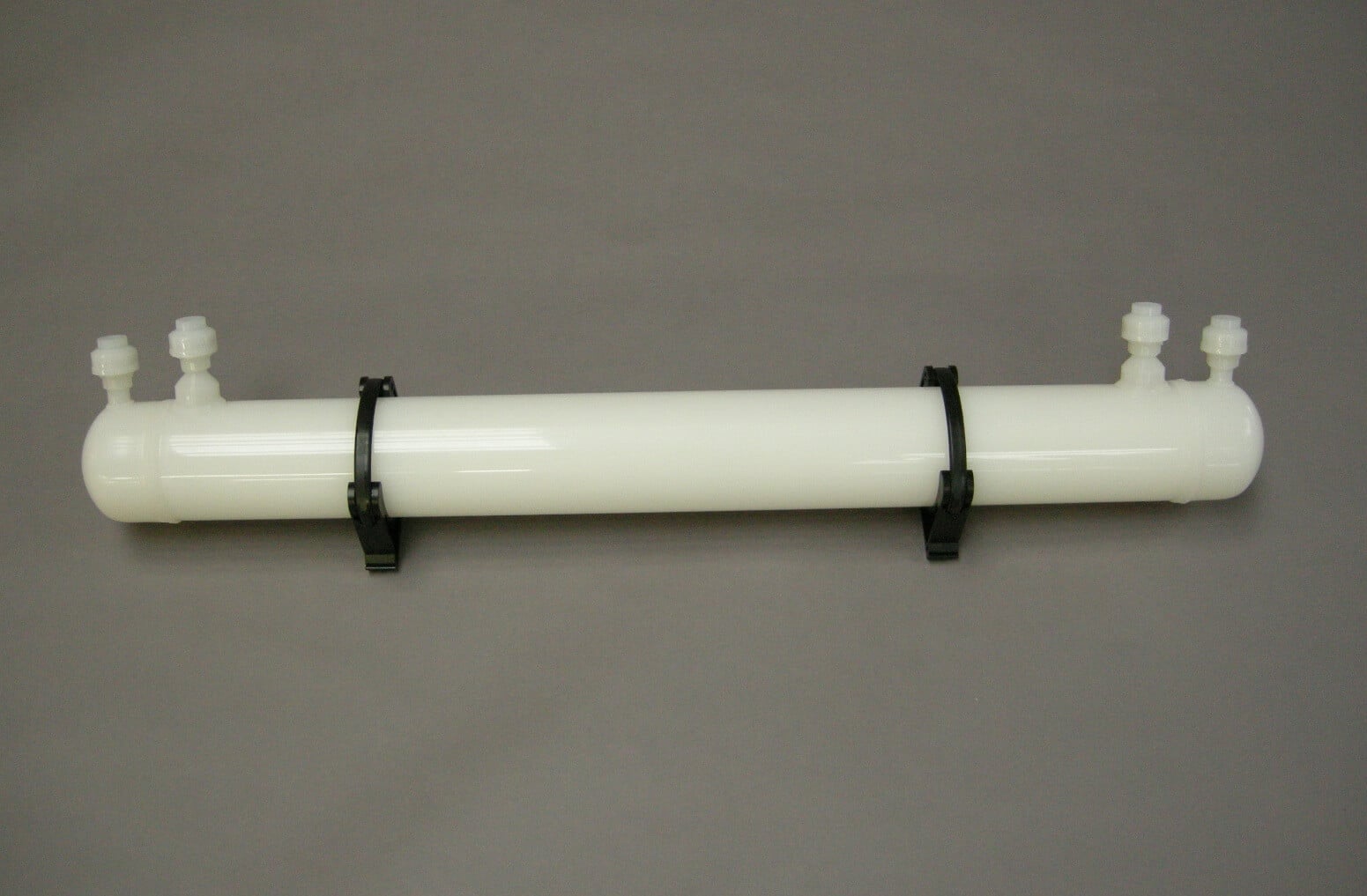

Introducing the CALORPLAST thermoplastic shell and tube heat exchanger – an external heat exchanger designed for cooling, heating, condensing or evaporating high-purity media. Our all-plastic heat exchanger features a compact design and a high heat transfer capability thanks to the use of thin-walled, non-fouling tubes.

The tube bundle, with its tube sheets, can be welded or bolted within the shell of the heat exchanger, allowing for the use of various material types for the design. With low pressure drop at approximately 1.45 to 7.25 psi, our heat exchanger is resistant to almost all corrosive media, resulting in low maintenance costs.

Our heat exchangers are also easy to clean with liquids and low-pressure steam (depending on the material used). Trust CALORPLAST for a reliable and efficient heat exchanger solution that meets your specific needs.