For more than 30 years Calorplast has specialized in the design, fabrication, and installation of plastic tanks. Our plastic tanks are designed and built in accordance with DVS standards created by the German Welding Society.

Calorplast USA has the ability to fabricate plastic tanks of any size, shape, and material. Our versatile manufacturing capabilities make it possible for us to accommodate the needs of each customer.

Thermoplastic materials of construction include:

- Polypropylene

- Polyethylene

- PVDF

- ECTFE

- PVC

- CPVC

- FEP

- PFA

Plastic Tank Applications

- Plating Tanks

- Galvanizing Tanks

- Corrosion Resistant Tanks

- Acid Tanks

- Process Tanks

- Rinse Tanks

- Pickling Tanks

- Water Tanks

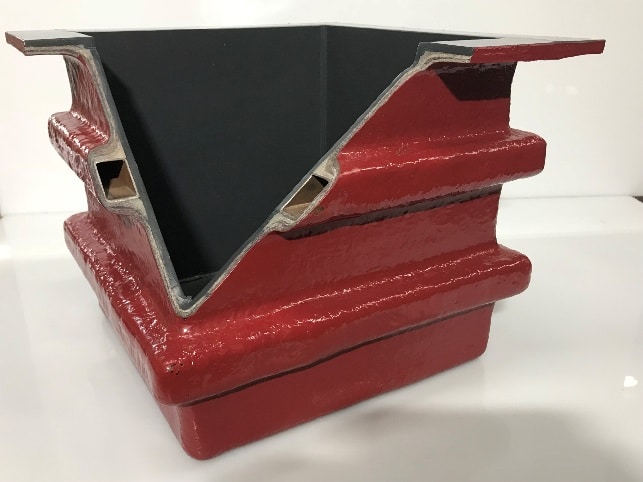

Thermoplastic/FRP Dual-Laminate Tanks

For many tank applications the corrosion resistance of thermoplastics is required along with the structural strength of fiberglass. For these applications the best solution often is to utilize a dual-laminate tank construction.

Dual laminate is a hybrid system made of fiberglass FRP structure outside and specialized thermoplastic or fluoropolymer liner inside. The thermoplastic liner is permanently bonded to the fiberglass outer structure. The liner is matched to chemical corrosion resistance requirements to optimize longevity including the ability to withstand high temperature requirements or abrasion resistance. Dual-laminates are often the best solution for the harshest chemical tank fabrications. Calorplast USA can fabricate custom dual-laminate tanks to provide a safe and long-lasting chemical storage solution